In the vast starry sky of the textile industry, there are always some companies that have become the bright stars leading the development of the industry with their excellent quality, exquisite craftsmanship and spirit of continuous innovation. Tongxiang Jinwei Textile Co., Ltd., as a Woven Fabric manufacturer, is such a dazzling star. Since its establishment, the company has always been committed to the research and development, production and sales of high-quality woven fabrics, providing diversified fabric solutions for global customers, and has won wide praise and trust.

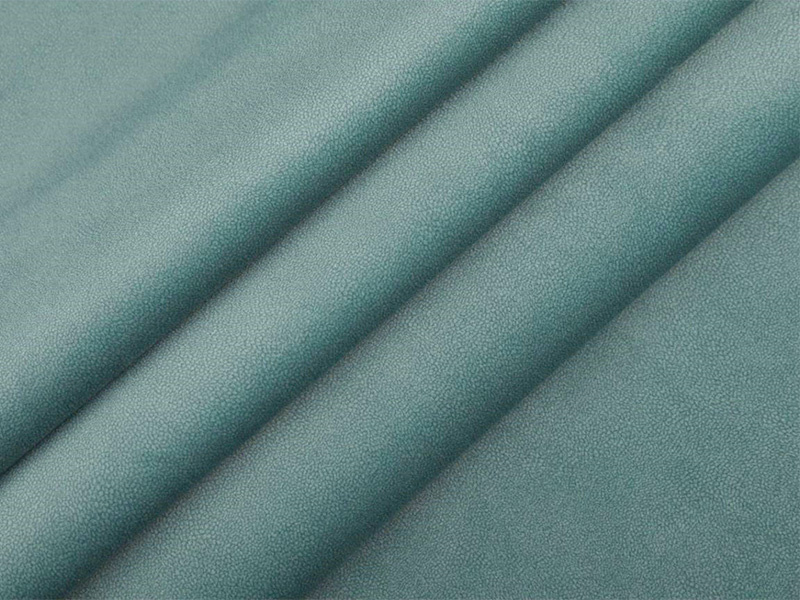

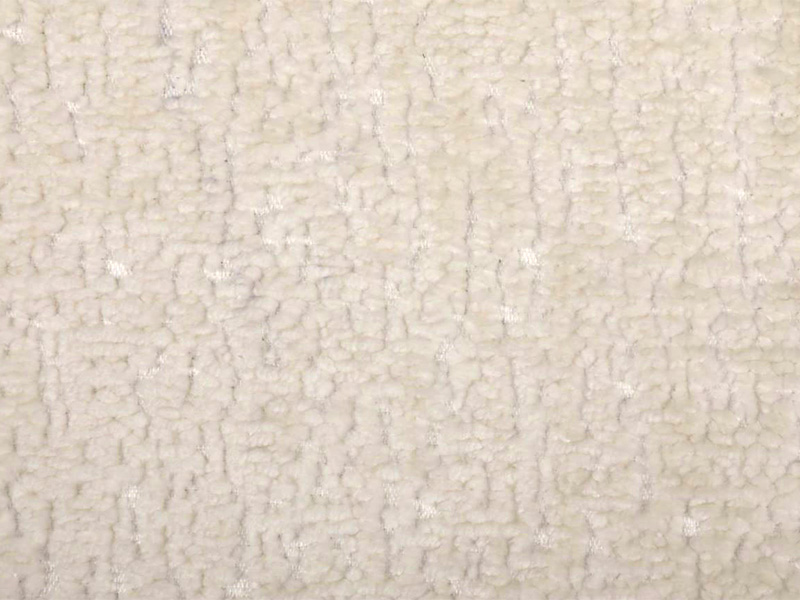

Tongxiang Jinwei knows that quality is the lifeline of the enterprise. From raw material procurement to production and processing, to finished product inspection, every link strictly follows international standards and industry specifications to ensure that every meter of fabric can meet or even exceed customer expectations. The company selects high-quality fiber raw materials at home and abroad, such as high-quality cotton, polyester, nylon, etc., and transforms the raw materials into delicate, durable and environmentally friendly woven fabrics through advanced spinning and weaving technology. At the same time, the company also has an experienced technical team that continuously develops new fabrics to meet the market's diversified needs for functionality, fashion and sustainability.

In today's world where textile technology is changing with each passing day, Tongxiang Jinwei has always been at the forefront of industry technology, actively introducing and independently developing advanced production equipment and technology. The company is equipped with modern production equipment such as high-speed air jet looms and rapier looms, as well as advanced fabric testing instruments to ensure that both production efficiency and product quality are improved.

Faced with increasingly severe environmental problems around the world, Tongxiang Jinwei actively responds to the national green development strategy and integrates environmental protection concepts throughout the entire process of production and operation. The company uses environmentally friendly dyes and auxiliaries to reduce wastewater and waste gas emissions, implements strict wastewater treatment measures, and ensures that the impact of production activities on the environment is minimized. At the same time, the company is also actively exploring a circular economy model, recycling waste fabrics and scraps, maximizing the use of resources, and contributing to the construction of a green, low-carbon, and circular textile industry system.

High-quality service is the key to winning customer trust. The company has established a complete pre-sales, in-sales, and after-sales service system to provide customers with one-stop services from fabric selection, design customization to logistics distribution. The company has a professional customer service team that can provide personalized fabric solutions based on the specific needs of customers to ensure the continuous improvement of customer satisfaction.

English

English русский

русский